Vacuum Pump Inlet Trap For Heavy Contaminant Vacuum Processes

A high-capacity vacuum pump inlet trap designed to remove high quantities of contaminants from LPCVD, PECVD, MOCVD, HVPE, ALD and similar processes has been introduced

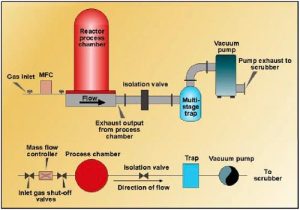

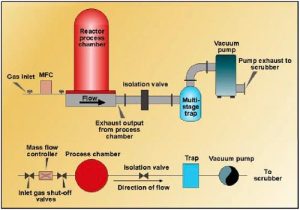

The dry pump on one reactor running silicon nitride failed, on average, every two months. This process deposits a 750 nm film over the course of five hours. The user performed routine maintenance every 50 runs, or after every 37,500 nm of deposition. To reduce the maintenance and the catastrophic pump failures, the user installed a threestage trap, consisting of a knock-down stage, a water cooling stage, and a filtration stage consisting of long stainless steel mesh filter elements (Figure 2). The trap proved to be efficient, allowing the time between routine maintenance to be doubled to 100 runs, or every 75,000 nm. The trap has successfully protected the dry pump from failure for well over one year.

Figure 2. A multi-stage trap in the foreline of an LPCVD system protects from catastrophic pump failure.

Upon disassembly of the trap during routine maintenance, the user found heavy accumulations of ammonium chloride in the knock-down and water cooling stages. Apparently, the ammonium chloride remained in vapor phase until reaching the sharp pressure drop provided by the knock-down stage. Additional ammonium chloride condensed out in the water cooling stage as the exhaust vapor cooled. A fine dust deposited on the stainless steel gauze elements, probably silicon nitride particulates.

A few rough calculations show that improving this vacuum system provides a huge payback:

1) Loss of a production run due to a pump failure could occur every two months before installation of the trap. After installation, no losses have occurred in more than one year. Assuming this is one of the first process steps on the wafer, we can look at the loss of one production run simply as the cost of the product wafers themselves: 1 run/2 months x 12 months/year x 100 wafers/load x $150/wafer = $90,000 per year savings.

2) Pump rebuild frequency drops from six times per year to less than once per year. At $6,000 per rebuild, the cost reduction per year is: 6 x $6,000 = $36,000 per year savings

3) Downtime for preventive maintenance drops in half, increasing the reactor throughput. Assuming 100% equipment utilization and four hours downtime each time preventive maintenance is performed on the vacuum system, the minimum effect on the throughput can be calculated:

Downtime before installation: 4 hours / 250 hours operation

Downtime after installation: 4 hours / 500 hours operation

Minimum throughput increase: 4 hours additional operating time / 500 hours operation = 0.8%

(Note: Using a capital cost of $1,000,000 for this reactor, this 0.8% capacity increase can be evaluated at 0.8% x $1,000,000 = $8,000, more than twice the cost of the trap.)

When installed on a new reactor from a different manufacturer, a multi-stage trap configuration shows similar results, with 98,000 nm of deposition between preventive maintenance and no pump failures to date. In this case, the exhaust line between the furnace and the trap is heated to prevent condensation before the gas reaches the trap, creating the same effect as a water cooling stage in the trap.

In another example, a second reactor by the same manufacturer was outfitted with a fourstage trap. This trap included the knock-down stage and water cooling, followed by a stainless steel gauze filtration stage and a 20-µm polypropylene filtration stage. The combination of the stainless steel gauze and the polypropylene filtration creates the same net result as the long stainless steel filter elements. In this case, preventive maintenance requirements dropped from once every 30 runs to once every 52 runs. The user has reported no pump failures after installation of the multi-stage trap.

A high-capacity vacuum pump inlet trap designed to remove high quantities of contaminants from LPCVD, PECVD, MOCVD, HVPE, ALD and similar processes has been introduced

A line of robust vacuum pump exhaust traps for use with dry scroll pumps to remove carbon soot which can damage recirculation systems has been introduced

Cleaning up an LPCVD Silicon Nitride Deposition System A typical application for a multiple-stage vacuum pump trap is a reactor that deposits silicon nitride (Si3N4)

Throughput Increases in Silicon Dioxide Deposition Systems Another common application for a multiple-stage vacuum pump trap is a CVD (chemical vapor deposition) process to deposit

Multi-Stage Traps Clean Up Vacuum Systems Cleaning up an LPCVD Silicon Nitride Deposition System A typical application for a multiple-stage vacuum pump trap is a

Multi-Stage Traps Clean Up Vacuum By Herbert W. Gatti and Lise C.H. Laurin The costs involved in maintaining vacuum processes in a manufacturing facility can

247 Rangeway Road

PO Box 359

North Billerica, MA 01862-0359

P: 978 667 2393

F: 978 671 0014

Email: sales@massvac.com

© 2024 MassVac Inc.

Webdesign by Turek Design